High-torque fastening systems are specifically designed to withstand extreme forces, making them indispensable in sectors such as automotive, aerospace, construction, and heavy machinery. This article explores the key features, applications, innovations and challenges of high-torque fastening systems, highlighting their significance in enhancing structural integrity and operational efficiency.

What are High-torque Fastening Systems

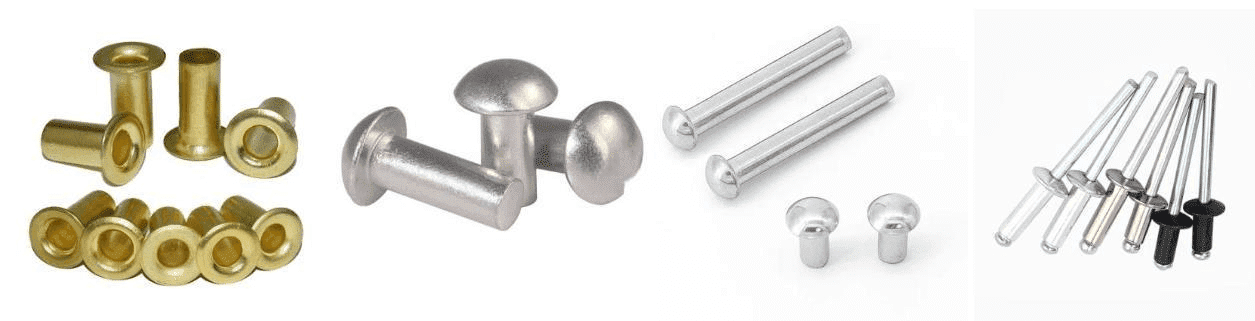

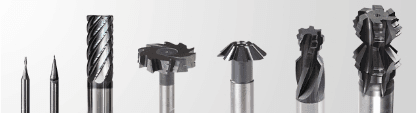

High-torque fastening systems refer to mechanical assemblies engineered to transmit or resist significant rotational forces (torque). These systems typically include bolts, screws, nuts, and specialized washers designed to maintain strong joints without loosening, even under heavy dynamic loads, vibration, or thermal stress.

Key Components of High-torque Fastening Systems

This chart summarizes the essential components of high-torque fastening systems, highlighting their individual roles and how they contribute to secure, reliable connections in demanding applications.

| Component | Description | Purpose |

| Bolts and Screws | Fasteners with high tensile strength, designed for heavy-duty use. | To secure two or more components under significant torque. |

| Nuts | Threaded fasteners that pair with bolts to hold components together. | To complement bolts, ensuring a secure and tight fit. |

| Washers | Thin, flat components placed between a fastener and the surface. | Distribute load evenly and prevent damage to surfaces. |

| Flanges | Circular or semi-circular components used to clamp and secure parts. | Improve torque transmission and ensure stability. |

| Locking Mechanisms | Includes lock washers, thread-locking adhesives, or self-locking threads. | Prevent loosening due to vibrations or dynamic forces. |

| Serrated Washers | Washers with ridged or serrated surfaces that grip the contact surface. | Enhance resistance to vibrations and prevent loosening. |

| Threaded Inserts | Internal threads placed in materials to accept bolts or screws. | Provide strong, reusable fastening points in softer materials. |

| Torque Indicators | Devices that show the applied torque during installation. | Ensure accurate tightening and prevent over-torquing. |

Key Features of High-Torque Fastening Systems

- High Tensile Strength: Designed to withstand significant loads, these systems use materials like alloy steel, titanium, or hardened stainless steel to ensure maximum durability and load-bearing capacity.

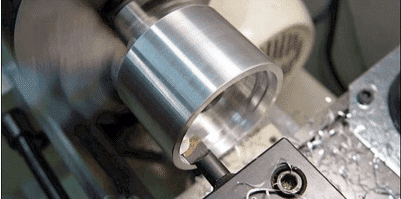

- Precision Machining: Fine threading, tight tolerances, and optimized geometries contribute to superior torque transmission and secure fitting, preventing failures under high-stress conditions.

- Anti-Loosening Mechanisms: Features such as self-locking threads, serrated flanges, and lock washers are integrated to resist loosening caused by vibration or dynamic loads.

- Corrosion Resistance: Protective coatings, such as zinc plating, anodizing, or advanced polymer finishes, enhance resistance to rust and environmental degradation, ensuring longevity in harsh conditions.

- Thermal Stability: Engineered to maintain performance across a wide temperature range, these fasteners are ideal for applications with fluctuating or extreme temperatures.

- Customizability: Available in various sizes, shapes, materials, and finishes to meet specific industrial requirements, ensuring compatibility with diverse applications.

- Ease of Installation and Maintenance: Designed for efficient assembly and disassembly, these systems often incorporate features like hexagonal heads or torque indicators to simplify operations.

- Enhanced Load Distribution: Specialized designs, such as flange bolts or washers, distribute stress evenly to prevent deformation or damage to the joined materials.

- Vibration Damping: Some systems include integrated vibration-damping materials or geometries to reduce noise and wear in dynamic environments.

- Lightweight Options: For weight-sensitive industries like aerospace, high-torque fastening systems are available in lightweight alloys or composite materials without compromising strength.

Applications of High-Torque Fastening Systems

This chart demonstrates the diverse use of high-torque fastening systems in industries that demand precision, strength, and reliability.

| Industry | Application | Purpose |

| Automotive | Engine assembly, chassis construction, drivetrain | Ensures secure and durable joints under high stress. |

| Aerospace | Aircraft structures, engine components | Withstands high-pressure and lightweight requirements. |

| Construction | Structural frameworks, heavy equipment anchoring | Provides stability in load-bearing applications. |

| Energy Sector | Wind turbines, oil rigs, power plant infrastructure | Resists corrosion and extreme environmental stresses. |

| Heavy Machinery | Cranes, excavators, industrial equipment assembly | Ensures reliability under heavy dynamic loads. |

| Marine | Shipbuilding, offshore platforms | Maintains integrity in corrosive and high-torque environments. |

| Railway and Transit | Track connections, train assembly | Withstands vibration and thermal fluctuations. |

| Renewable Energy | Solar panel mounts, hydroelectric turbines | Provides durability in weather-exposed installations. |

Innovations in High-Torque Fastening Technology

Recent advancements have further enhanced the functionality of high-torque fastening systems

- Smart Fasteners with Embedded Sensors: Modern high-torque fasteners are now equipped with embedded sensors that monitor real-time torque levels, detect loosening, and provide data for predictive maintenance. These innovations improve safety and operational efficiency by preventing failures before they occur.

- Self-Locking Systems: Advanced self-locking nut mechanisms eliminate the need for separate locking hardware, such as lock washers or thread-locking adhesives. These designs ensure a secure hold under extreme vibrations and dynamic loads, reducing installation time and cost.

- Lightweight High-Strength Materials: The development of advanced alloys and composite materials has led to fasteners that are both lightweight and exceptionally strong. These are particularly beneficial in industries like aerospace, where weight savings translate directly into improved performance and fuel efficiency.

- Eco-Friendly Coatings: New environmentally friendly coatings provide superior corrosion resistance without using harmful substances like cadmium or hexavalent chromium. These coatings are durable, cost-effective, and compliant with stringent environmental regulations.

- High-torque Screws with Anti-Galling Properties: Anti-galling treatments, such as specialized surface finishes or coatings, reduce friction and wear during installation, ensuring consistent performance and extending the lifespan of screws.

- Multi-Function Fasteners: Innovations include fasteners that combine multiple functionalities, such as integrated washers, torque indicators, or locking mechanisms, into a single component to simplify assembly and enhance reliability.

- Aerodynamic Fastener Designs: For applications in industries like automotive and aerospace, fasteners with streamlined designs minimize drag, contributing to better energy efficiency and overall system performance.

- Improved Torque Control Mechanisms: Torque-limiting designs integrated into fasteners provide precise torque control during tightening, reducing the risk of over-torquing and potential damage to components.

- Nano-coatings for Enhanced Performance: Nano-coatings offer improved resistance to wear, corrosion, and extreme temperatures while maintaining a low-friction surface, ensuring optimal performance in demanding applications.

Challenges in High-Torque Fastening Systems

This chart helps identify common challenges while providing actionable solutions to enhance the performance and reliability of high-torque fastening systems.

| Challenge | Description | Possible Solutions |

| Material Wear and Deformation | High torque can lead to wear, deformation, or stripping of threads in fasteners and joints. | Use stronger materials (e.g., high-grade steel, titanium) and proper lubrication. |

| Joint Loosening | Vibrations and repetitive loads may cause the fastener to loosen over time. | Incorporate locking mechanisms (e.g., thread-locking adhesives, lock washers, or double nuts). |

| Torque Control Precision | Difficulty in applying consistent torque across all fasteners. | Utilize torque wrenches or automated tools with precise control features. |

| Heat Generation | Friction during fastening can cause heat buildup, leading to material weakening. | Use lubricants to reduce friction and dissipate heat effectively. |

| Corrosion and Environmental Factors | Exposure to moisture, chemicals, and extreme temperatures can degrade fastener integrity. | Choose corrosion-resistant materials (e.g., stainless steel, coatings) and implement seals. |

| Overloading or Fatigue | Sustained high torque or overloads may lead to fastener fatigue and failure. | Perform load analysis and ensure fasteners are rated for the intended loads. |

| Compatibility Issues | Mismatch between fasteners, materials, and application surfaces. | Conduct compatibility testing and use standard fastener dimensions and materials. |

| Cost Constraints | High-performance materials and precision tools can increase costs. | Optimize material selection and explore cost-effective solutions without compromising quality. |

In summary, high-torque fastening systems are essential for industries demanding robust, precise, and durable solutions for securing mechanical components in challenging conditions. Their innovative designs and advanced materials make them a cornerstone of modern engineering.